top of page

A sophisticated, minimalist coffee hand grinder designed as a thoughtful exploration of how to practically integrate sustainability into product design, creating a better future without sacrificing the product quality and user experience.

Duration: 8 Weeks

Project Time: Summer 2024

Skills Demonstrated: Innovation | Design for Sustainability | Form Development | Storytelling

Benchmark Product Study

Issues with current design

Unrepairable,

Unrecyclable

Plastic parts were permanently attached to metal components, making repairs impossible and forcing customers to discard the entire product when it malfunctions. This construction also makes the metal unrecyclable.

Project Goal

To explore a new path where sustainability and user experience thrive together

Interviews

Kevin Kwon

Coffee Barista, Sydney, Australia

“I find inner peace in the process”

Maxim Bregs

Coffee Barista, Los Angeles, CA

“I enjoy the sensation of the burr grinding the beans and the smell of freshly ground coffee.”

Raphael Li

Coffee Enthusiast, Cambridge, MA

“Well designed and high quality tools really reduce the friction of the learning process for me.”

Insights

It's more than just brewing a cup of coffee.

Coffee enthusiasts savor the aroma of freshly ground beans.

Coffee enthusiasts delight in the clatter of beans colliding.

Coffee enthusiasts enjoy the tactile sensation of burrs grinding the beans

Coffee enthusiasts treasure the mindful moments of brewing coffee.

Product Pain-Points

Findings were gathered from interviews, YouTube reviews, Amazon reviews, and coffee forums.

Flawed design can cause beans to bounce out during loading.

Loose parts will undermine the user experience.

The adjustment knob tends to get dirty and cluttered.

Fine grounds get stuck in small gaps, causing fitment issues.

Mission Statement

Designing the perfect manual coffee grinder that tackles all the existing pain points and meets the internal desires of coffee enthusiasts, while also making the production, usage, and recycling processes more environmentally friendly through thoughtful design.

Trend Research

As consumer values shift towards more responsible lifestyles, CMF design is going through a transformation, veering away from disposability and moving to longer-lasting materials and finishes

2023 CMF Trends

Design for Longevity

When considering a purchase most consumers value durability (58%), reparability (39%) and biodiversity (37%) over recyclability or biodegradability

2023 Customer Behavior Trends

Durability & repairability

lead the way

Design Process

Sustainability Strategies

Less is More

Minimize Parts

Minimize Material Diversity

Minimize Using Virgin Material

Minimize Manufacturing Process

Ideation

Prototyping

User Testing

MUGEN

Premium Coffee Accessories

Inspired by the Japanese word "Mugen," meaning infinity,

the brand embodies the essence of timelessness. The aim is to create products built to last a lifetime, serving as a constant companion throughout every coffee lover's journey, standing the test of time with enduring quality and craftsmanship.

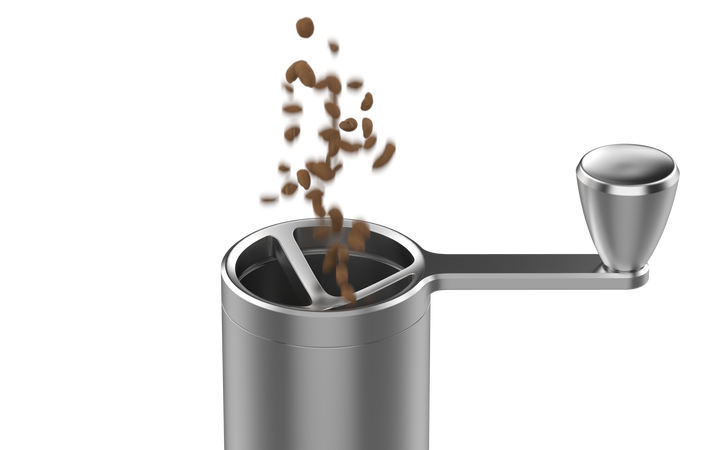

Signature Feature

Open-Top Design

This design streamlines the user experience and reduces operational friction, also minimizes the number of components, which reduces the likelihood of malfunction and lowers energy consumption during the manufacturing process.

Open-Top Design

Beyond Functionality

The design subtly amplifies the satisfying sound of burrs grinding beans, allows the aroma of the fresh grounds to be more pronounced. It caters to the internal desires of coffee enthusiasts, elevating their overall satisfaction and enjoyment.

Grind Adjustment Ring

Dial in, Simple and Precise

The external adjustment ring makes dialing in grind size easy and mess-free. The intuitive indicator graphics allows you to swiftly and accurately switch grind sizes for different brewing methods.

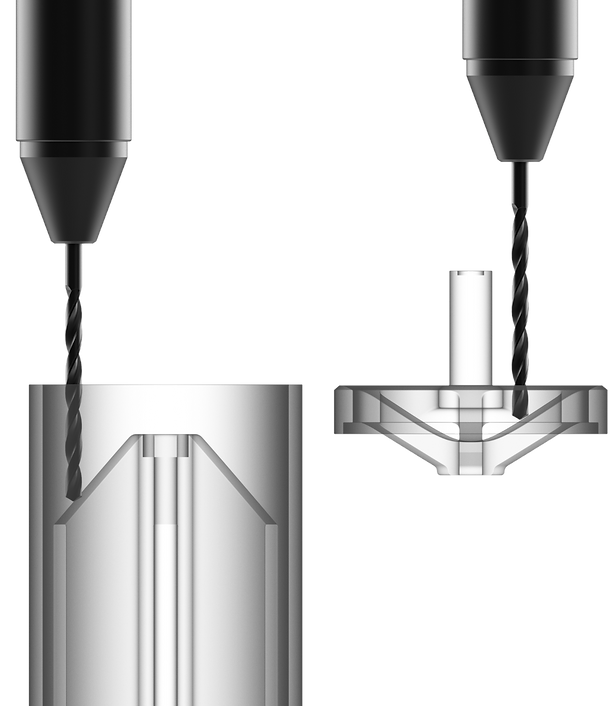

Attention to

the Unseen Details

Designed to avoid tiny gaps and sharp corners, preventing coffee grounds from getting trapped

—for a cleaner, smoother using experience.

Traditional Solution

MUGEN Solution

Grind size Adjustment Mechanism

Simple Change, Huge Difference

Traditional solutions adjust grind size by moving the inner burr. Simply shifting to moving the outer burr achieves the same effect, streamlining the structure and reducing parts.

than traditional designs

35% Less Parts

This not only ensures less material and energy use throughout production but also reduces the likelihood of malfunctions over long-term use.

Magnetic Connection

Plain Bearing

Drive Shaft

Spring

48mm Burrs

Adjustment Ring

Magnetic Connection

50 gram Max Capacity Canister

Designed for

Effortless Disassembly

No special tools required. With a streamlined structure, it's designed for easy part replacement—so you can update your grinder effortlessly.

Internal Structure

Optimized for CNC

Every major component is optimized for seamless CNC integration, reducing part count and plastic consumption, while enhancing long-term reliability.

THANK YOU.

bottom of page